Listed among the

topmost companies, we offer Jet Vacuum Systems and Ejectors to

the client. This range of Vacuum Systems and Ejectors is made by professional’s

team using high grade material and advanced technology in compliance with the

set quality standards. In addition to this, our products undergo various tests

under the supervision of quality controllers to ensure its flawlessness.

Steam jet

vacuum systems can be designed for various applications:

·

Vacuum / steam jet cooling systems

·

Vacuum degassing systems

Compressed air driven

vacuum ejectors find a wide use in the industry due to the easy availability of

Compressed air which acts as a motive medium in these ejectors. These devices

are extremely reliant, and highly compact in size.

Contrary to Steam

based vacuum ejectors they do not require cooling water / chilled water for

functioning and also don’t require auxiliary equipment such as condensers,

condensate pumps and hotwells. The only required input is compressed air.

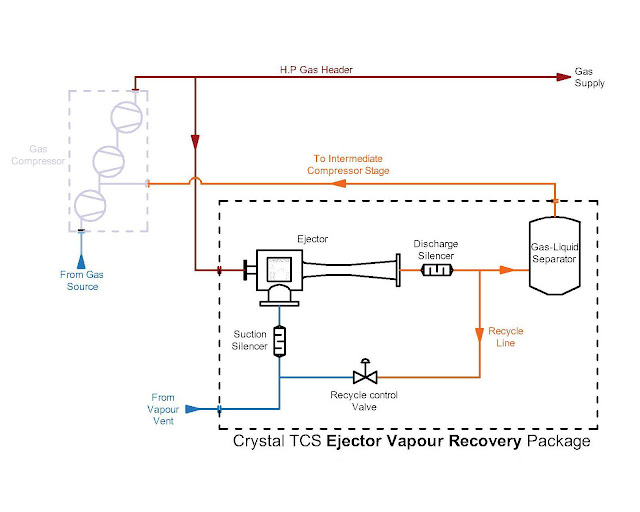

One

of the ways to create vacuum is by using Vacuum Ejector systems. Ejectors are simple devices, having no moving parts, which

depend on the variation in the geometry of their internal passages for

producing vacuum.

These units can

be designed to operate with compressed air over a large range of pressure and

temperature. In fact higher the available compressed air temperature lower will

be the flow requirement, thus eliminating the need for an after cooler in a

compressed air system.

We manufacture

Ejectors in different materials such as Carbon Steel, Stainless Steel and

Hastelloys. The material selection is done after making careful assessments and

taking due considerations of the process mediums.

Compressed air

driven ejectors are generally used in single stage configuration. Multi stage

systems can be designed upon request. Compressed air ejector are most reliable

and maintenance free among the ejector range.

Features:

·

Strong

design

·

Easy

to use

·

High

quality

Crystal TCS has

committed itself to continued research in the field of its applications which

has helped us to be coherent with the markets. We ensure an efficient product

life-cycle experience to our Client not only by precise and quality products

but also through equally competent after-sales services.

We are a company established in 2012 and based in Nashik,

Maharashtra, India The company is promoted by Directors having a rich and

diverse experience of more than 30 years in the field of Capital Equipment and

Engineering.

For more information

Give us call at:

+91 253 2501600

jet vacuum system | Vacuum

Ejector manufacturers | Vacuum Ejector suppliers

| Vacuum Ejector in

nashik | Vacuum

Ejector in pune |